Série TD-30 - Fonctionnalités

Systèmes de désorption thermique

Outstanding Processing Ability and Basic Functionality

Extensive Sample Capacity Capable of Accommodating 120 Samples

The TD-30R has a maximum capacity of 120 samples, which allows processing a large number of samples via consecutive analyses overnight and on weekends. In addition, the sample tray is positioned lower down on the front of the instrument. This makes it easy to access even during analysis, and prevents tube positioning errors.

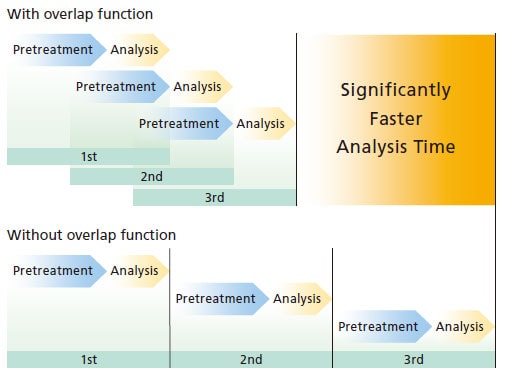

Efficient Analysis with the Overlap Function and Interrupt Function

With the TD-30 series, the overlap function enables the next sample to be pretreated during GC analysis, which shortens the analysis cycle time. In addition, the interrupt function enables unscheduled samples to be inserted even during consecutive analysis. As a result, a sample can be added after checking the results for a different sample, and an urgent sample analysis request can be accommodated.

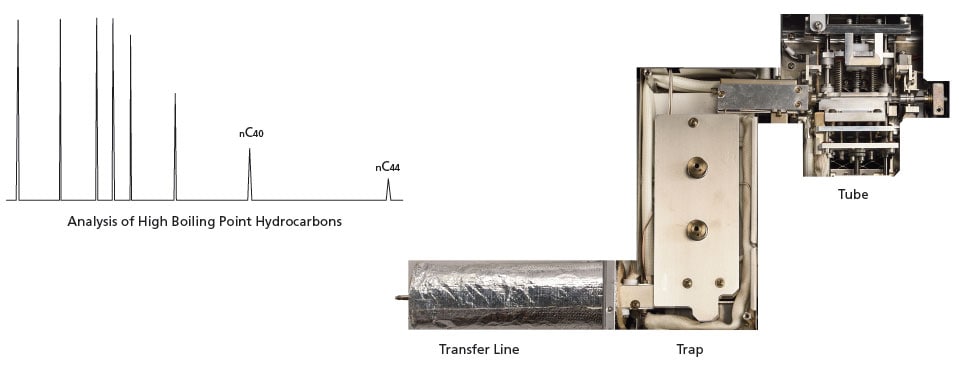

High-Sensitivity Analysis of High Boiling Point Components Using a Sample Line with No Cold Points

With the TD-30 series, the entire sample line can be heated, so there are no cold points.

In addition, the sample line, including the transfer line, is designed to be short, which minimizes dead volume, and even highly adsorbent components and high boiling point components can be analyzed with high sensitivity.

Excellent Expandability Enables a Variety of Analyses

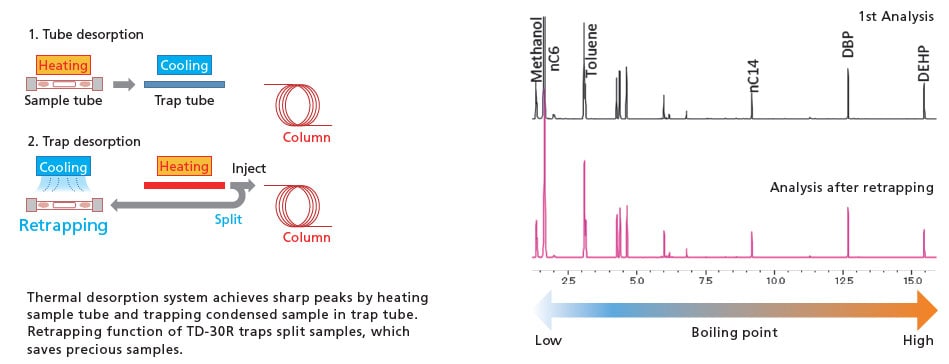

Hedging Risks with the Retrapping (Restore) Function

With the retrapping (restore) function, split samples desorbed from the tube and loaded into the GC-MS are once again trapped by the tube. Even if a problem occurs, the sample can be measured again, so that even precious trace samples can be analyzed with a sense of ease. In addition, with the TD-30R, the tube is cooled rapidly after desorption, so even low boiling point components can be restored.

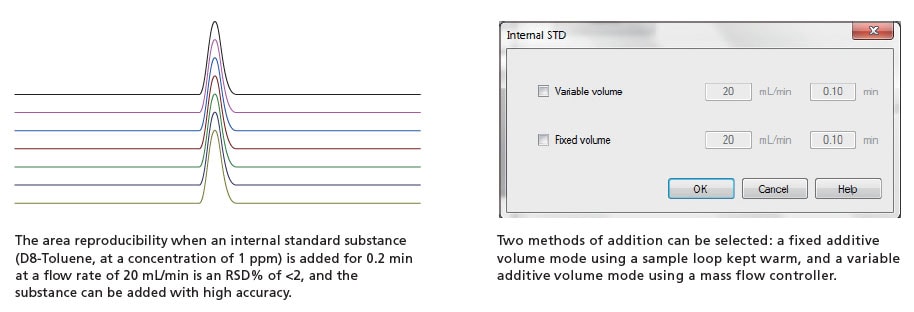

Highly Accurate Quantitative Analysis Using a Function That Automatically Adds an Internal Standard Substance

The TD-30R can automatically add a gaseous internal standard substance to the sample tube.

Highly reliable quantitative results can be obtained, even for the analysis of trace components.

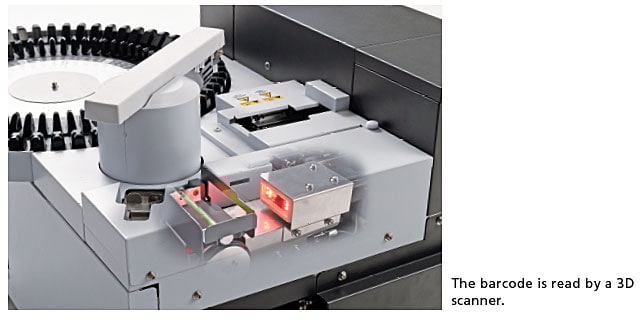

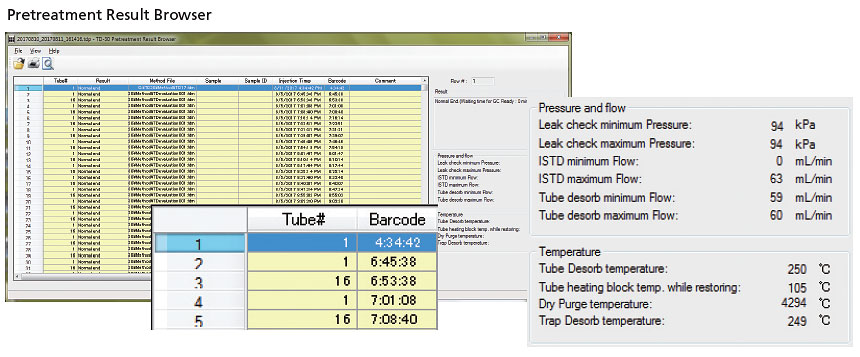

Highly Reliable Sample Management Using a Barcode Reader Function

The TD-30R can be optionally equipped with a barcode reader function. The barcode printed on the tube can be automatically read, and the tube and sample information recorded by the software.

Furthermore, the conditions when the tube was analyzed can be easily checked.

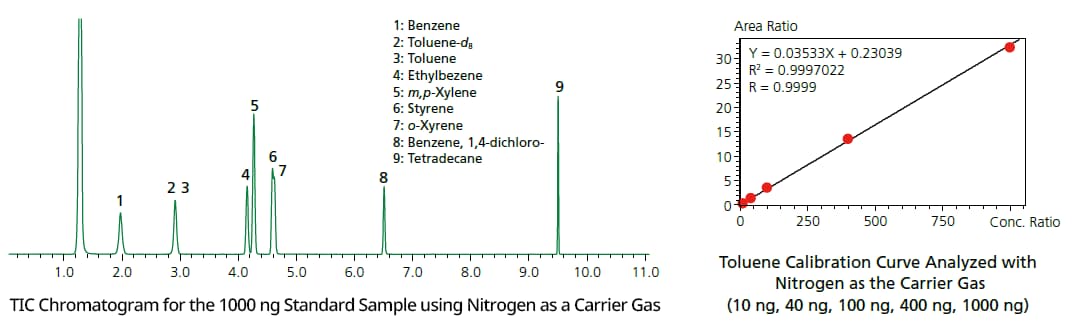

Nitrogen and Hydrogen Carrier Gas Compatibility with GCMS

Using nitrogen carrier gas can sometimes complicate matters involving sensitivity and operability with GCMS systems. However, the Shimadzu TD-GCMS system includes functionality to perform auto-tuning with nitrogen carrier gas as well as other improvements to ensure smooth operation. Furthermore, Shimadzu TD-GCMS can also make use of Hydrogen as a carrier gas. During programmed temperature analysis, it is a well-known fact that linear velocity varies as the temperature increases. To address this, Shimadzu GC units utilize constant linear velocity control to provide optimal separation, not only for helium but also for both nitrogen and hydrogen.

Simple Operations and Ease of Maintenance

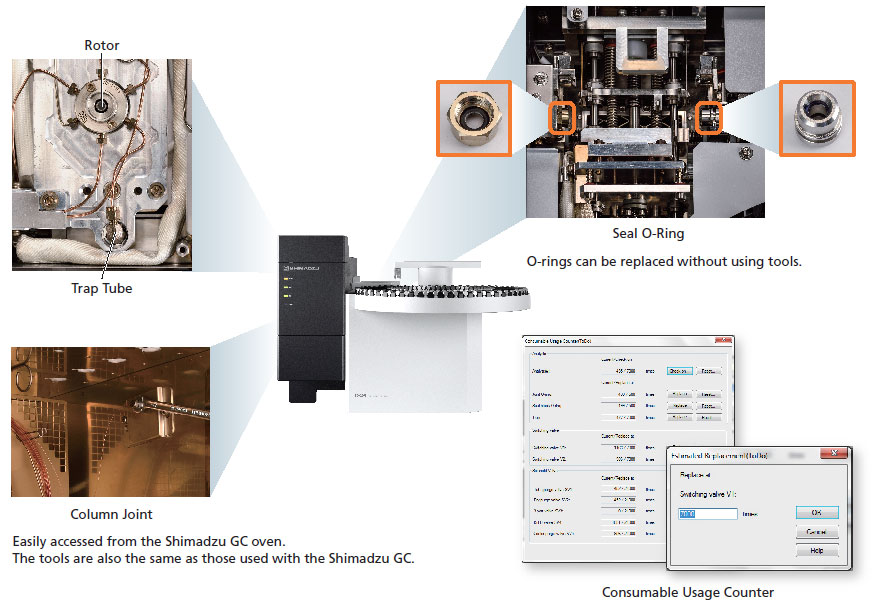

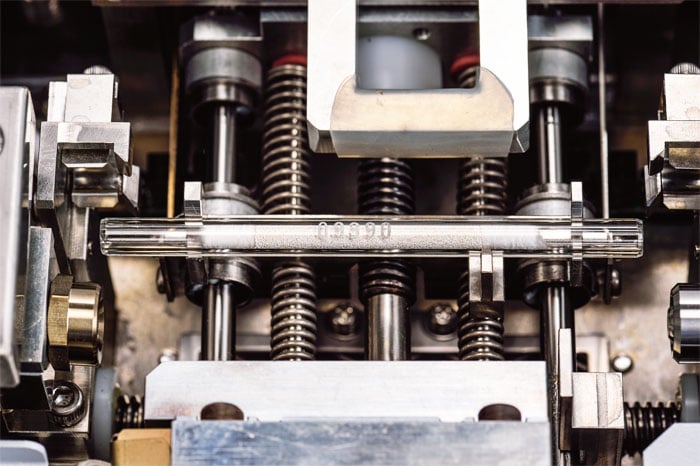

Easy-to-Maintain, User-Friendly Design

With the TD-30 series, traps, O-rings, and other consumables and maintenance parts can be accessed from the top surface of the instrument, so replacement is simple.

The system is equipped with a software function that records the number of uses of consumables and maintenance parts, and notifies the user when a pre-specified number of uses has been reached. Accordingly, problems due to the operating life of parts can be avoided.

Problems with Tubes Are Prevented Using the Tube Protection Function and the Pressure Release Function

The TD-30 series features a built-in tube protection sensor, which significantly reduces tube damage during cap removal.

In addition, before the tube is removed, the pressure inside the tube is reduced, extending the tube's lifetime.

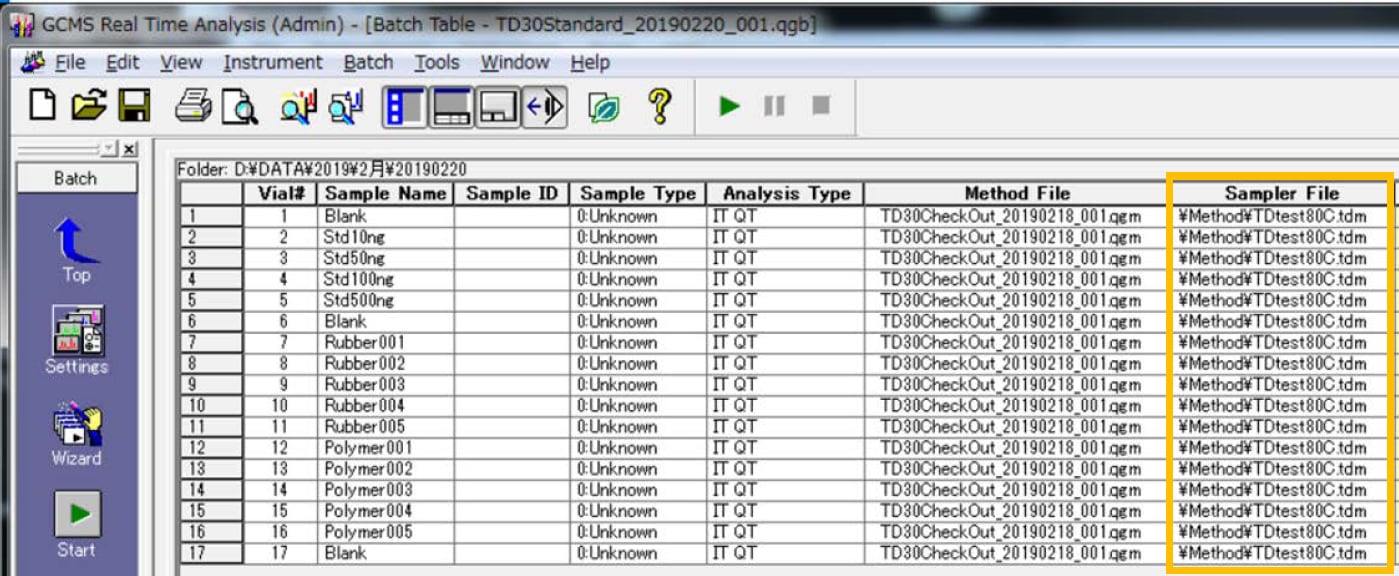

Reliable Analysis Is Simple to Implement with GCMSsolution Software

Method files for the TD-30/30R can be set for a GCMS batch using the optional software GCMSsolution TD Add-in.* Both GCMS and TD can be controlled from GCMSsolution without the need for additional software. This not only improves operability, but also prevents mistakes in applying settings.

*GCMSsolution TD Add-in is not compatible with LabSolutions GC. Overlapping will be deactivated by installing the Add-in.

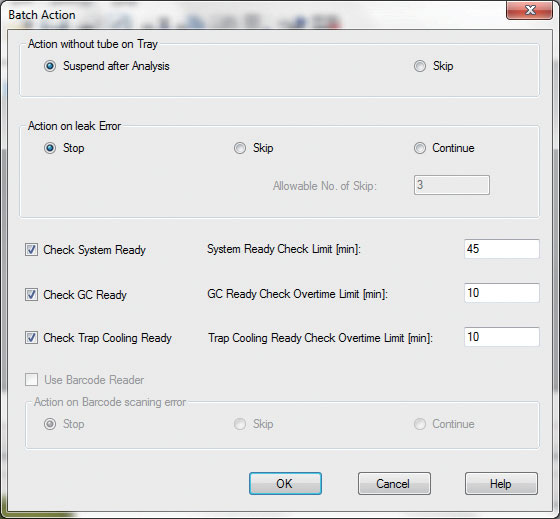

Appropriate Measures When an Analysis Error Occurs (Skip Function)

If a user forgets to place a sample in the tray, or a leak error is detected due to a defective product, it's possible to select whether to stop the consecutive analysis, or skip that step and continue. As a result, precious time is not wasted by simple mistakes.

Effective Instrument Management Using Various Tools

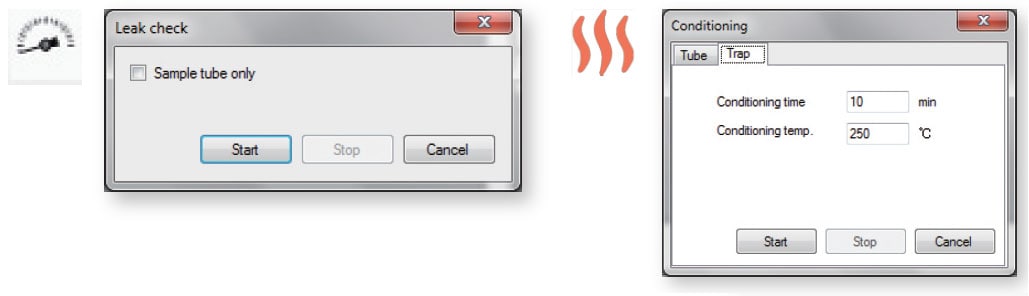

The independent leak check function can be used for confirmation after maintenance, and to confirm the status of the sample tubes.

By using the trap tube conditioning function, users can reduce the background noise immediately after trap tube replacement.